What’s the best way to capture comprehensive measurement data in an underground tunnel?

To answer that question, I recently joined project surveyors in taking the Leica MS60 MultiStation 200 feet underground to test its capabilities on a tunnel survey. After posting a video on LinkedIn of the MS60 at work (see below), I received a number of requests for more details on this application. Below is the rest of the story.

The Right Tool for the Job

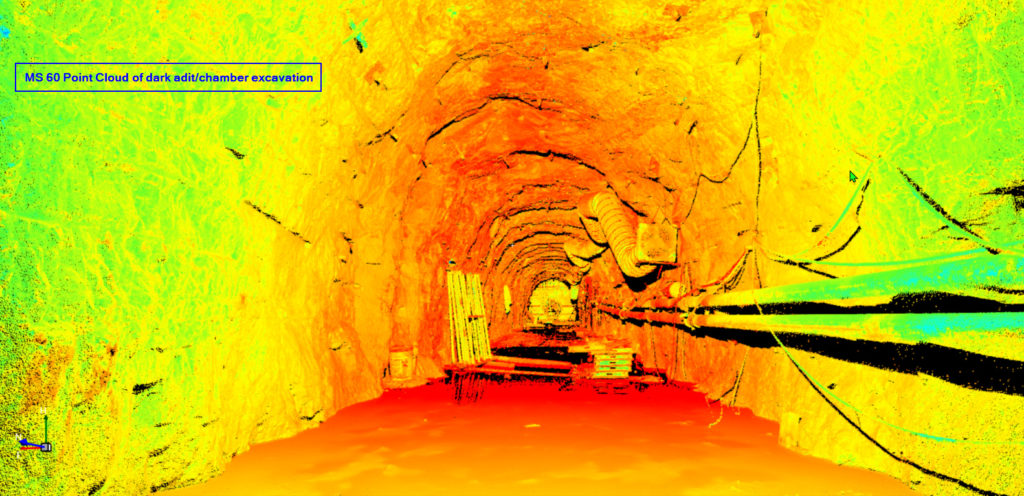

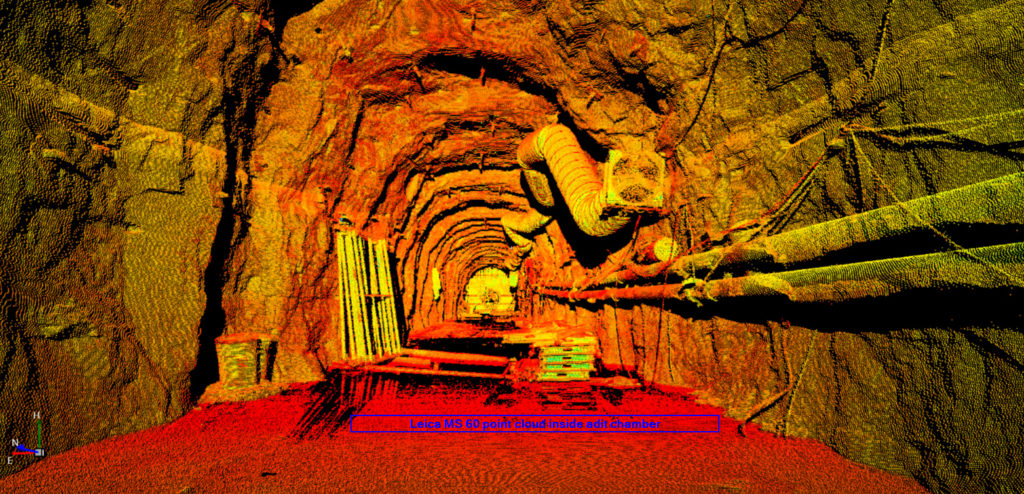

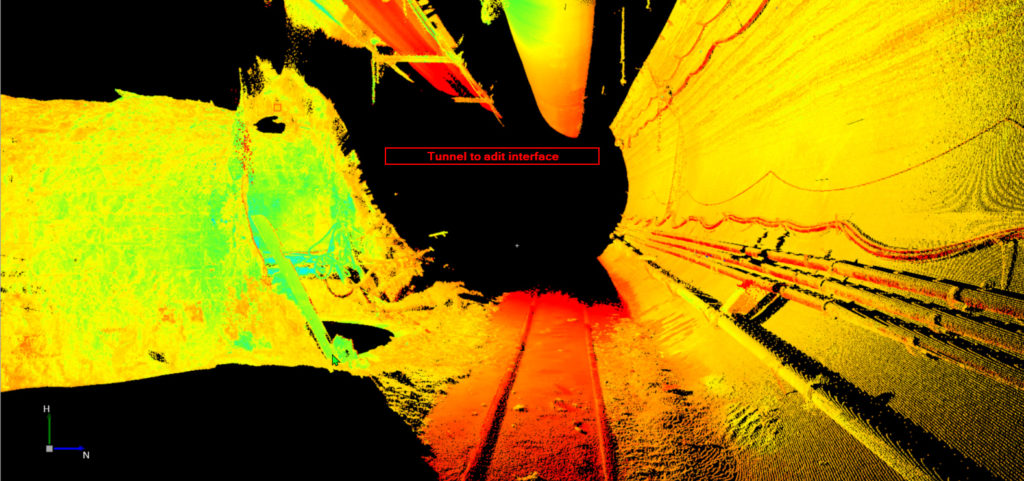

The objective was to collect as-built data on an adit and chamber excavation. The inaccessibility of some areas of the tunnel required surveyors to bring the right tools from the outset. The MS60 is a scanning total station with 1-second angular accuracy, which enables it to be used effectively on layouts as well as control surveys, where highly accurate and precise measurements are needed. It also includes several tunnel-specific software applications, including Measure Tunnel, Check Tunnel and Inspect Surfaces. “While the scanning hardware allows us to collect data, when paired with some of the Captivate apps it allows us to check the existing conditions instantaneously with project design,” said one project surveyor. “This is a great time and cost savings for our operation.”

The surveyor noted that their previous process required the crew to collect data and bring it back to the office to run comparative checks against design. Then, after results were determined, they would take another trip to the worksite to mark any discrepancies. “It is a fair statement to say that this hardware/software has cut that workflow in half!” he said.

Several other capabilities also made the MS60 ideal for this application. For example, it provides the ability to complete all survey tasks, such as resection. Additionally, the laser pointer makes finding prisms in dark tunnel shafts very easy.

The Benefits of a Band Scan

Using the MS60, the crew performed a two-point resection to get on the correct tunnel coordinate system. Then they defined two band scans: one from Zenith to approximately 90 degrees, and the second from 90 degrees down to the floor.

The band scan capability allowed the crew to be highly selective of the area on which they wanted to collect data. Combined with the faster scan rates of the new MS60, this capability decreased the time per scan, which, in turn, increased productivity.

It’s worth noting that the crew could have performed a full dome scan and achieved the same results. But what if you only need data for the ceiling of the shaft, or maybe only the bottom 5 feet of the walls? With the band scan method, you have full control over setting up and collecting the required data.

The selected scan definitions can be saved and referenced again in the future for monitoring progress or ensuring that project specifications are met. Scan definitions can also be shared between instruments to keep the entire project team in alignment.

Related: On-Demand Webinar Provides Practical Advice for Entry-Level Laser Scanning

Accuracy Plus Efficiency Yields Increased Survey Success

The as-built data captured from the tunnel survey is being used to compare to the design diameter of the adit/chamber as well as to calculate the volumes of backfill material needed for the overbreak. By using the MS60, the crew was able to perform all of the required surveying tasks accurately and with serious gains in productivity. According to the project surveyor, “The band scanning function is a useful feature that will help us collect data accurately and increase overall efficiency on the project.”

To talk to me or one of our other experts and learn more about how to maximize efficiency in your surveying business, please contact us.

About the Author:

Steven Myer has more than 25 years of experience in the surveying and engineering professions. As geomatics sales, support and training specialist for Leica Geosystems in the Indiana-Ohio region, Myer focuses on providing innovative, real-world solutions to some of the industry’s toughest challenges. Follow Steven on LinkedIn.