The ability to track and respond to movement in real time gives project teams confidence in handling large-diameter tunnel boring projects.

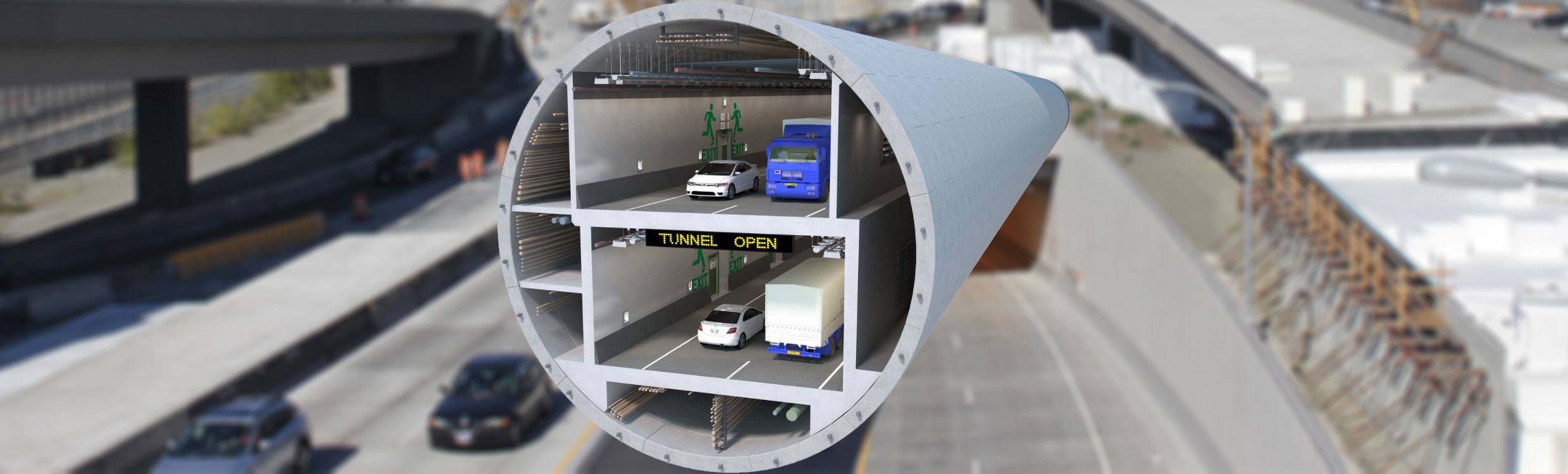

At just two miles, the State Route 99 tunnel in Seattle (also known as the Alaskan Way Viaduct Replacement Tunnel) was not an especially long tunnel boring project; however, it was a record breaker in terms of diameter. That’s partly because it’s not a rail tunnel; instead, the tunnel functions more like an underground bridge for cars, with two generous two-lane freeways stacked on top of each other. That takes a lot of volume, and a very large-diameter tunnel—57.5 feet, to be exact. For comparison, the tunnels being bored in New York’s East Side Access project (currently in the running for world’s biggest ongoing tunnel project) never exceed 22 feet in diameter.

The Seattle tunnel is so big, in fact, that a brand new, $80 million tunnel boring machine (TBM) was created especially for the project by Japan’s Hitachi Zosen Corporation, and shipped to Seattle in 41 pieces. When assembled, “Bertha”—the name was picked by Seattle elementary school students—was 326 feet long and weighed 6,100 tons.

This giant machine dug the world’s widest tunnel at a rate of 6.5 feet per day, directly underneath Seattle’s historic Pioneer Square and the downtown business district—an area with high groundwater and notoriously unstable soils. After several delays, work was completed in April 2017, and the tunnel was opened to traffic in Feb. 2019. Throughout the project, monitoring the boring process, and the precise positions of the buildings and other infrastructure directly overhead, was important to Seattle area businesses and residents.

“It’s not that good monitoring can prevent damage, or collapses—there are a lot of risks and threats that simply can’t be predicted. But, monitoring can help tunnel boring projects to react well to changing conditions, and to react sooner.”

– SIXENSE Project Manager Loic Galisson

A Model of Precise Monitoring

It’s not as if tunnel collapses are unheard of; in 2009 a rock fall idled a mega-TBM on a Niagara River water diversion tunnel for more than two months. And even right in Seattle, tunnel projects have run into trouble. A July 2013 article in the Puget Sound Business Journal noted:

“It will be up to… Seattle Tunnel Partners to make sure things go smoother (on the viaduct) than for King County Metro’s Brightwater sewage tunnel near Bothell, or for Seattle’s Beacon Hill Sound Transit light rail tunnel. Work on Brightwater stopped for months in 2009 when a tunnel-boring machine was damaged. At Beacon Hill, construction worker Michael Merryman died in a 2007 accident, and the digging opened “voids” in the earth and caused house foundations to crack.”

“There have been a lot of projects where there were huge damages,” concedes Loic Galisson, a project manager for SIXENSE (at the time called SOLDATA), a Seattle-based firm that specializes in risk mitigation on large construction sites. “And in many cases, the damage is increased because there is little or no monitoring. It’s not that good monitoring can prevent damage, or collapses—there are a lot of risks and threats that simply can’t be predicted. But, monitoring can help tunnel boring projects to react well to changing conditions, and to react sooner.”

SIXENSE was the subcontractor charged with monitoring aboveground changes during the tunnel boring. The firm understood that they were dealing with a special challenge; “In some ways, this was very similar to projects we’ve completed in Europe and Asia,” Galisson explains. “But on the other hand, this was really a very big tunnel, one of the biggest ever drilled, so everyone was wondering how it would turn out.”

To cope with the unknowns, SIXENSE assembled one of the most comprehensive and sensitive monitoring networks ever attempted, a network that has deployed about 4,000 sensors that rely on dozens of separate technologies, including extensometers (measure vertical deformation of the ground), inclinometers (measure horizontal movement of the ground), piezometers (measure static pressures in fluids, usually groundwater), crack and strain gauges (applied to beams and other building supports), several types of levels and tiltmeters, and even some radar interferometry. All of these were in addition to thousands of sensors on the TBM itself.

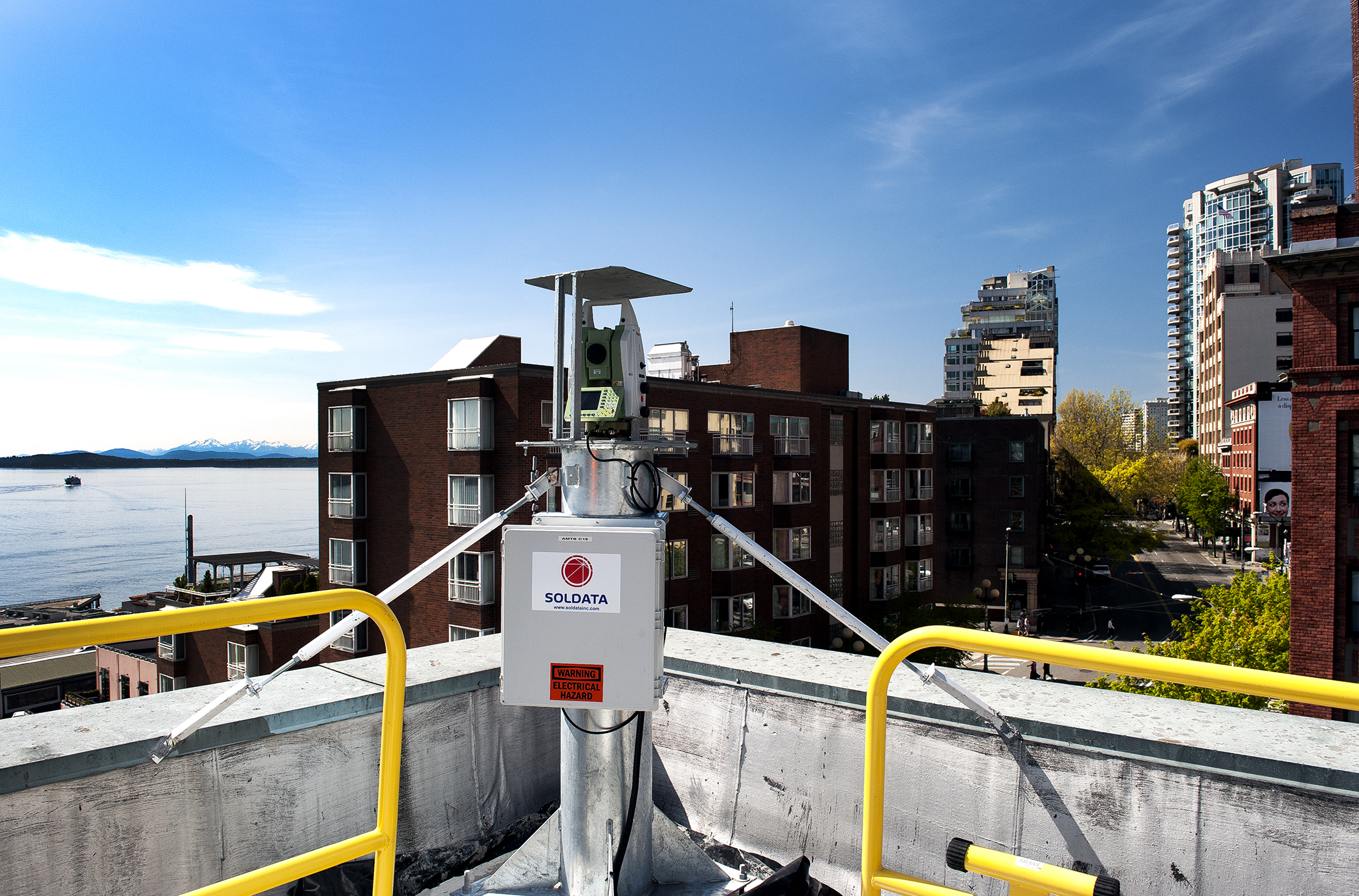

But the most visible of the sensors—and the ones that most captured the interest of Seattleites—were TM30 total stations, made by Leica Geosystems. These were specialized instruments, built for real-time monitoring. SIXENSE set 37 of them in permanent locations on (and, in two cases, under) buildings and roadways covering the projected tunnel path. SIXENSE referred to the TM30s affectionately as “Cyclops” or “Centaur,” and it’s fair to say that they were the heart of the network; all 37 were connected 24/7 to a web-based GIS, and each of them automatically measured about fifty points in cycles lasting 20 to 30 minutes. Very small positional changes—as small as a quarter inch and up to an inch, depending on ground conditions and the type of structure being measured—would immediately sound alerts that were conveyed to TBM crews and, in some cases, could shut down Big Bertha more or less automatically.

It was a lot of responsibility, and Galisson and his staff took their work very seriously. A team of 18 was onsite for several months prior to boring commencement, designing and installing the network, and establishing baselines for building movement. A team of six remained onsite for the entire dig, “watching screens!” Galisson says cheerfully. Completely automatic reporting wasn’t feasible with a sensor network this size, and SIXENSE staff spent a lot of time “monitoring the monitoring,” with someone keeping on eye on onscreen reports continuously. And obviously, a lot of time was spent checking, maintaining, calibrating, repairing, and replacing all the many sensors.

Designing the TM30 network alone took many weeks. Engineers used existing surveys and aerials to designate the most important and desirable locations for total stations. The actual spot was important, as project specifications called for the TM30s to remain in place throughout the 14-month construction phase. “We discussed ‘leapfrogging’ the stations along the tunnel path, as the TBM progressed,” Galisson says. “But ultimately, having consistent readings of one big set of positions is more important than minimizing the number of Cyclops used.” So SIXENSE wanted, basically, secure locations with good views of critical points, and they wanted these to be distributed evenly along the bore path. Having established ideal locations, they then compromised as needed. “We had a theoretical optimum, of course,” Galisson explains, “but in some cases we couldn’t get access to buildings, and we also tried to minimize tree trimming.”

Vandalism or theft, of course, had to be considered. Most of the aboveground TM30s were set on rooftops with key-controlled access, or on secure public structures, and most were also set inside covered steel cages. And every TM30 was equipped with an anti-theft system that covers the tribrach and prevents unauthorized adjustments.

Leica Geosystems worked closely with the SIXENSE project management team through all phases of this project. To begin, the Leica Geosystems team had to prove to SIXENSE that the TM30s would perform throughout the demanding weather seasons expected in Seattle, so they tested the instruments on another SIXENSE project that had similar precipitation levels. Once approved, they had to meet the demanding installation schedule and provide them with guarantees of available backup instruments if needed.

With all instruments installed and performing to their expected standard, the monitoring work could begin.

Working with the Data

Analyzing the data from 4,000 sensors, in real time, and then reacting, if necessary, immediately is obviously a world-class feat of analysis. The day-to-day operation of the TM30 network was controlled by proprietary software that SIXENSE called TACT, for Target Acquisition Controlled by Theodolite.” Similar to the Leica GeoMoS automatic deformation monitoring system, TACT directed each TM30 to cycle through its assigned series of measurements, compiles the readings, and uploads to other systems as needed.

To manage the data, SIXENSE used a proprietary web-based GIS called GEOSCOPE. “Its strength was to be able to collect data from nearly any kind of sensor and to combine various types of data sources to analyze ground behavior, or any another environmental phenomenon,” explains Galisson. “We’d been building GEOSCOPE for the last 15 years, taking advantage of real experience and feedback from all our business units on the major urban construction projects in the world (Europe, Asia, Russia, North/South America). So it was a really flexible tool, adapted to construction, environmental monitoring, mine operations, etc. Addressing the specific requests we’ve had from our various clients made this software really powerful, and very well suited to user needs.”

Seattle is the site of one of America’s most ambitious landscape transformations; the Denny Regrade neighborhood. Now a flat triangular area just north of the central business district, it used to be a very large hill. In a series of massive projects extending from 1897 to 1930, Denny Hill was first dug up and leveled in spots via informal projects, then sluiced into Elliott Bay with hydraulic mining techniques, and then, finally, regraded completely with steam shovels. It goes without saying that none of this work was “monitored” in the modern sense. And, in fact, there were many disastrous landslides and unplanned home removals in Seattle’s regrade era.

So it’s a good thing that construction project monitoring has emerged as a surveying specialty in our time. Addressing the world’s massive infrastructure shortfalls will absolutely require that large, ambitious projects be undertaken in densely populated urban areas. As SIXENSE’s work on the Alaskan Way Viaduct Replacement Tunnel proved, monitoring is now a mature construction technology that is helping cities to remake themselves, safely and efficiently, without doing damage to existing buildings and landmarks.

Tunnel visualization (above): WSDOT – Original publication: https://www.flickr.com/photos/wsdot/4907983170/in/set-72157624760624786

To talk to one of our experts and learn more about solutions for surveying and monitoring, please contact us.