Confrontational landowners, aggressive dogs and venomous snakes are just a few of the unexpected challenges you might encounter in your day-to-day work as a pipeline surveyor.

More predictable but equally undesirable are the data management dilemmas: The tedious creation of databases and their subsequent conversion to commonly used pipeline software; the need to verify in the office all updates recorded in the field through a labor-intensive process that typically requires one office tech for every two to three field crews; and the manual data entry required for the necessary compliance reports. Even firms that specialize in time-sensitive pipeline surveying have struggled to overcome these obstacles.

Piecing Together Disjointed Workflows

Existing technology for pipeline surveying has been disjointed with a significant amount of manual data entry required. Survey firms have tried to implement code and field solutions with their data teams but have had problems standardizing codes and matching data between crews. Manipulation of data was required to get a graphical representation of the pipeline and associated features. The profession has long needed a way to achieve a standardized, automated workflow that would ensure accuracy and result in a superior product for clients.

Streamlining Surveys with an End to End Approach

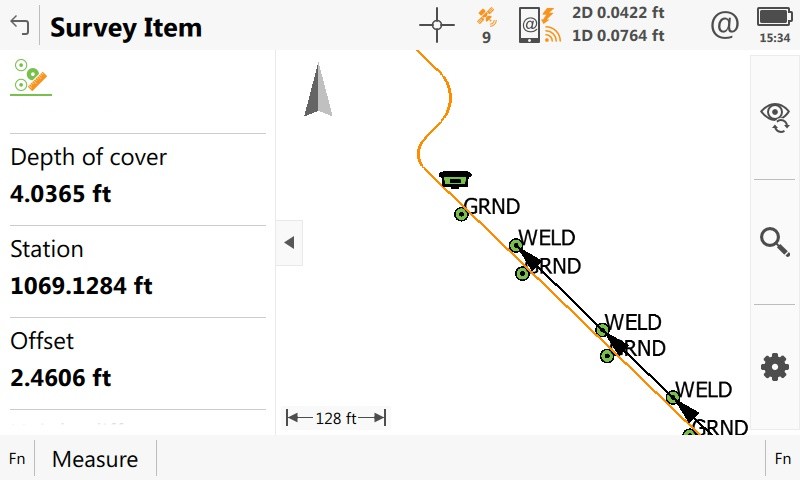

Guided by the insights of surveyors who worked on both the contractor and owner sides of the pipeline equation, as well as by experienced professionals who specialize in this field, a team from Leica Geosystems began working on a new highly automated application that would seamlessly connect the entire process, from inventory to layout to reconciliation. The result, Leica Captivate Pipeline, provides an entirely new way of dealing with the data.

Why Collaboration Was Key

Surveyors are notorious problem solvers who aren’t afraid of manual data entry. But the sheer inefficiency of the data manipulation required in the pipeline surveying workflow is mind boggling. Technology has made tremendous strides in the surveying and mapping process in the field but has previously overlooked critical elements—namely in the reconciliation of the shipping manifest originating from the steel mill (pipe manufacturer) and the map database showing where that pipe was placed in the ground.

Collaborating with pipeline surveying experts enabled the team to find and fill in the gaps to achieve a much higher level of automation across the entire workflow, which dramatically increases efficiency and reduces the risk of error. It’s an exciting development for the pipeline industry as a whole.

Higher productivity, reduced data ambiguities, improved data integrity, a consistent workflow … isn’t it time to check these goals off your list?

Note: A version of this article was originally published on LinkedIn. To learn more or request a demo, please contact us.