Deformation monitoring is becoming increasingly common on projects of all sizes, leading to new opportunities for surveyors.

Ten or twenty years ago, deformation monitoring was viewed as a highly specialized “niche” discipline. Today, that is changing. Deformation monitoring is becoming increasingly common on projects of all sizes, primarily as a result of two factors:

- The increasing availability and decreasing costs of specialized monitoring equipment and software, and…

- Increasing costs of infrastructure litigation and wider knowledge of automated monitoring capacities. We could also mention here all the worries caused by aging infrastructure.

Of course, these same two factors are at work in many areas of measurement technology—just as the lowered costs and increased availability of GPS receivers combined with wide knowledge of the usefulness of GPS led to GPS capacity in, well, everyone’s front pocket or purse, so the increasing commonness of automated monitoring solutions and widespread knowledge of their availability and utility is leading to regular use even on routine infrastructure projects. Put another way… we’ve heard a lot about monitoring flashy projects like the Washington Monument and Seattle’s Alaskan Way Viaduct, but fairly soon we’ll be seeing average-sized cities monitoring roadways over trenchless sewer rehabilitations, and contractors monitoring retaining wall construction. Automated deformation monitoring is about to become routine… but hopefully not boring!

Defining Deformation Monitoring

Just what is deformation monitoring? The Wikipedia definition is useful: Deformation monitoring (also referred to as deformation survey) is the systematic measurement and tracking of the alteration in the shape or dimensions of an object as a result of stresses induced by applied loads. Deformation monitoring is a major component of logging measured values that may be used to for further computation, deformation analysis, predictive maintenance, and alarming.

Deformation monitoring is primarily related to the field of applied surveying (Author’s note: Thank you!), but may be also related to the civil engineering, mechanical engineering, plant construction, soil and rock stability mechanics.

“You have every right to expect good visual interfaces with features like heat maps, highly sophisticated and customizable alarming features, easy integration of multiple sensors in one network, and powerful, scalable routines that make automated deformation monitoring of infrastructure assets a routine feature of modern construction and maintenance.”

“You have every right to expect good visual interfaces with features like heat maps, highly sophisticated and customizable alarming features, easy integration of multiple sensors in one network, and powerful, scalable routines that make automated deformation monitoring of infrastructure assets a routine feature of modern construction and maintenance.”

– Craig Hewes, PLS

Put very simply, deformation monitoring is used to measure and record spatial change over time, usually in manmade infrastructure assets but also in natural features such as cliff faces. The obvious reasons for deformation monitoring include potential construction-caused instability and asset movement due to erosion or subsurface instability, but there are many less obvious reasons such as landslide safety warnings, climate change measurement, and what we can call “failure warning” monitoring of assets that are simply getting old.

Specialized Equipment & Software

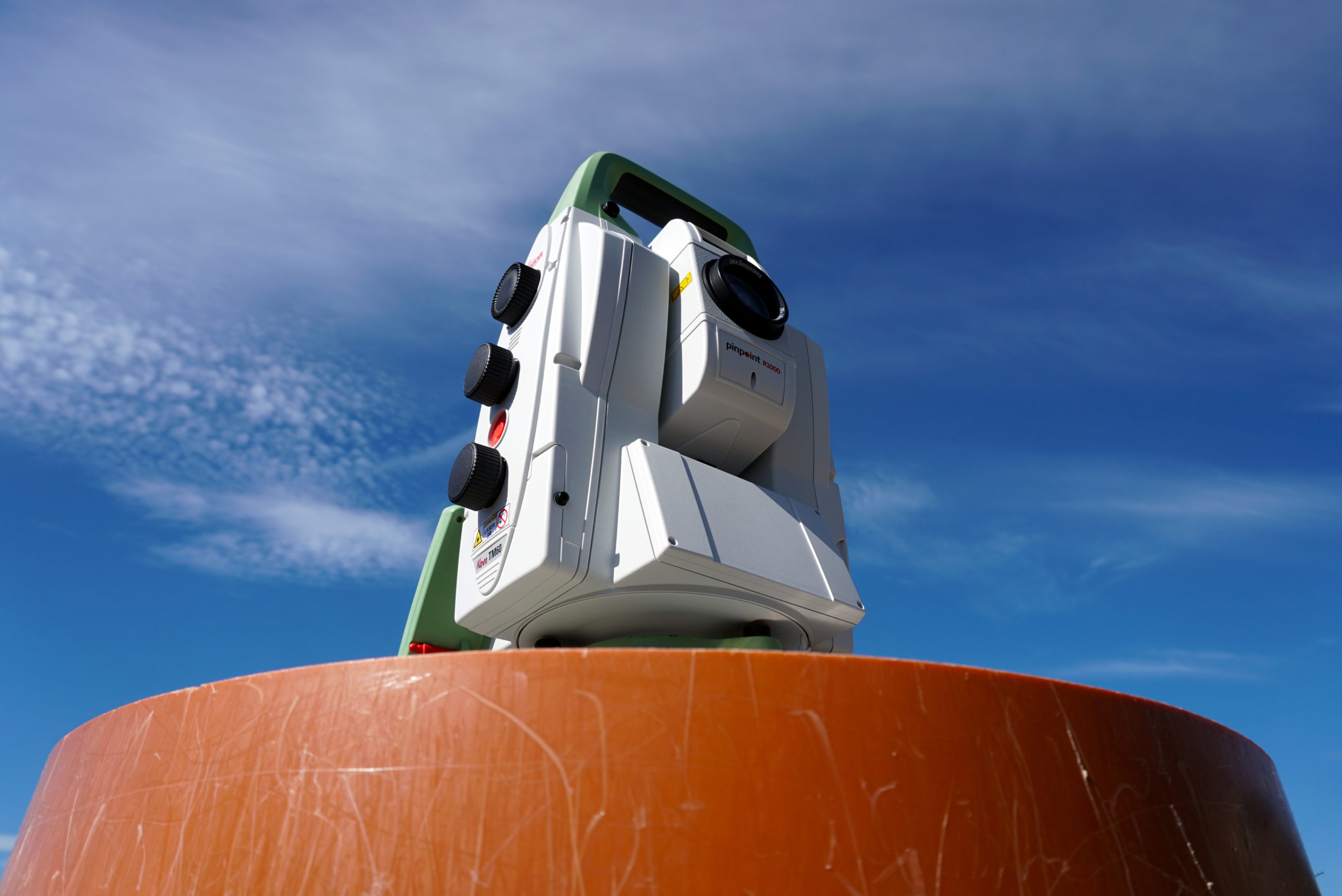

One of the clearest signs of the coming ubiquity of infrastructure deformation monitoring is the emergence of highly specialized monitoring hardware, as opposed to the adaptive use of existing sensors. Total stations—still the workhorses of deformation monitoring—are a good example. Just a few years ago, the majority of total stations used in monitoring setups were simply robotic total stations guided by automated routines and their Internet and/or radio communication was more or less improvisational. Now, total stations optimized specifically for monitoring are readily available. The Leica Nova TM50 Monitoring Sensor, for example, features a housing made with gravity-feed casting to be heavier and more rigid, for more consistent measurements over long periods. The TM50 is also our best total station for long range automatic targeting, an important feature for safe monitoring—it can find and lock on a prism nearly 10,000 feet away!

Similar specialization is available in our line of GNSS sensors, and Leica Geosystems has even developed scanning technology specialized for monitoring, such as mathematically modeled surfaces that are easily monitored for significant deformation.

And monitoring software solutions are also undergoing a quiet revolution. When evaluating automated monitoring systems, today’s surveyors have every right to expect good visual interfaces with features like heat maps, highly sophisticated and customizable alarming features, easy integration of multiple sensors (e.g., total stations, scanners, GNSS, inclinometers, etc.) in one network, easy access to emails and text messaging, more or less automatic incorporation of GNSS reference stations and RTK networks, and all the additional powerful, scalable routines that are making the automated deformation monitoring of infrastructure assets a routine feature of modern construction and maintenance.

We’re in the midst of yet another surveying and infrastructure revolution. Deformation monitoring is about to become routine on smaller and smaller projects, which means there will be more and more opportunities for surveyors and engineers to stake a claim in this growing and still-lucrative specialty.

About the Author:

Craig S. Hewes, PLS, is a licensed land surveyor who is experienced in supertall building construction and asset monitoring. For nearly 15 years, Craig served as Leica Geosystems' director of monitoring for the Eastern US and Canada. In his current role as Leica Geosystems' senior strategic account manager, Craig helps surveying and engineering organizations achieve new levels of success through a strategic partnership approach to technology adoption.

Craig S. Hewes, PLS, is a licensed land surveyor who is experienced in supertall building construction and asset monitoring. For nearly 15 years, Craig served as Leica Geosystems' director of monitoring for the Eastern US and Canada. In his current role as Leica Geosystems' senior strategic account manager, Craig helps surveying and engineering organizations achieve new levels of success through a strategic partnership approach to technology adoption.

To talk to one of our experts and learn more about solutions for surveying and monitoring, please contact us.