When high-speed wasn’t fast enough, McLaren Engineering Group turned to high-tech in the form of a handheld imaging laser scanner to deliver the ultimate value.

Challenging project schedules and complex site conditions are nothing new for most surveying and engineering firms. In fact, the best firms and most esteemed professionals have made a name for themselves by delivering exceptional results when the stakes are high. But what do you do when you find yourself in the middle of a project with seemingly insurmountable obstacles because of information you didn’t have at the outset? It happens to just about everyone.

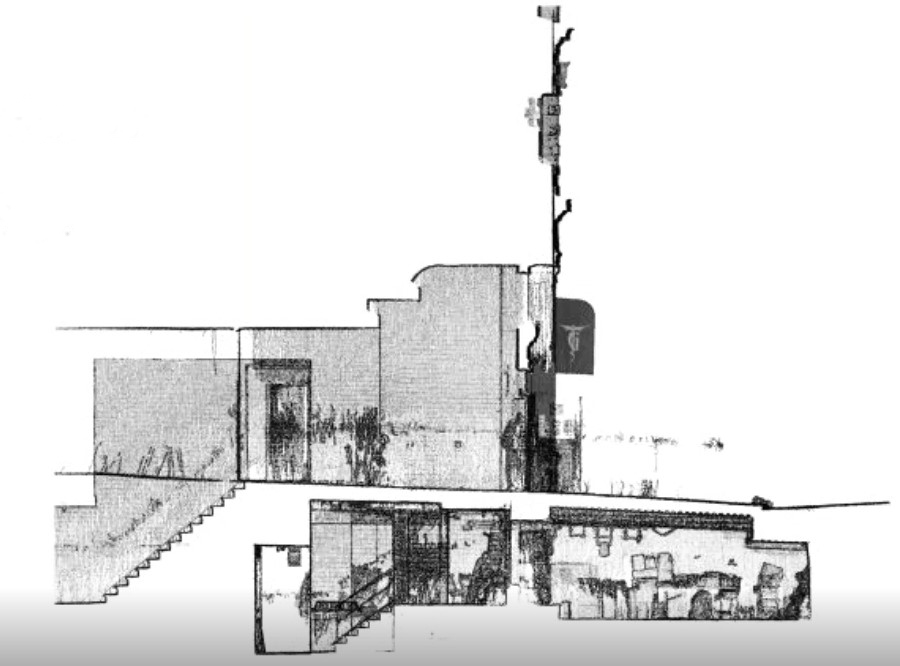

When McLaren Engineering Group was tasked with surveying vaults under New York City, the project appeared straightforward. The company needed to document 42 intersections in Manhattan and Brooklyn and investigate every property within 100 feet of those intersections to locate and then survey all the vaults — basements that extend beyond a property, typically into a road right-of-way underneath the sidewalk and even occasionally under the road itself.

“In Manhattan especially — and Brooklyn to a large degree — you can’t stick a shovel in the ground without hitting something,” explained Jason Larson, McLaren’s technical director, in a webinar on surveying ingenuity and innovation. McLaren was appointed to make sure that “something” was not a vault.

“When we looked at the numbers, it became pretty clear that the BLK2GO was going to be a killer tech for this type of application, so we pushed forward with purchasing one and moved on with the project.”

“When we looked at the numbers, it became pretty clear that the BLK2GO was going to be a killer tech for this type of application, so we pushed forward with purchasing one and moved on with the project.”

– Jason Larson, PLS

The project encompassed 700 properties, each of which fit one of four scenarios: Type 1: No vault; Type 2: no access to the vault; Type 3: a vault under 100 square feet in size; or Type 4: a vault over 100 square feet in size. Surveying the vaults would include measuring/mapping the extent and shape of the vault, measuring the elevation of the floor and ceilings, capturing photography, and preparing drawings and reports for the deliverables.

The timeline to complete the project was three months, with payment under contract in the form of a lump sum unit price based on what was known or assumed about the vaults.

What wasn’t known about the vaults, however, would turn out to be one of the biggest challenges Larson had faced in his career.

Overcoming Project Challenges with Technology

Concern over COVID-19 meant that the McLaren crews needed to avoid spending large amounts of time on other people’s property. Where accessible vaults did exist, the entrances were often circuitous and full of awkward geometries, which made traditional surveying approaches difficult at best.

As the crews got a firsthand look at all the properties, Larson realized another unsettling truth: Most of the vaults were Type 1 and 2, rather than the higher-unit-price Type 3 and 4 that had been projected. Of the 700 properties, only 147 had vaults that could be accessed and surveyed. Due to the pricing structure of the project, efficiency was of the utmost importance.

“To be successful on this project, we had to maximize our field effort,” said Larson. “We couldn’t just do one or two vaults per day; we had to do five, six or seven per day to make it work financially.”

Larson, who has extensive experience with laser scanning, considered using a terrestrial laser scanner for the project but realized that even the compact, ultra-high-speed Leica RTC360 would be too bulky and slow to meet the project objectives. However, he was curious whether the vaults would be a good application for the new handheld imaging laser scanner, the Leica BLK2GO, which creates a digital twin as the operator walks through a space.

Larson reached out to his local Leica Geosystems technical representative, Bruce Marquis, who gave the team a technology demo in McLaren’s office. Larson then used the BLK2GO to capture a vault under the McLaren office building in Manhattan for proof of concept.

“You can just walk in and walk out, so that was definitely going to be the shortest exposure time,” Larson explained. “We just had to convince ourselves that that was going to be the best method.”

The McLaren team calculated the estimated cost of other possible measurement methods, factoring in the labor hours and cost of equipment.

“When we looked at the numbers, it became pretty clear that the BLK2GO was going to be a killer tech for this type of application, so we pushed forward with purchasing one and moved on with the project,” Larson said.

Flexible, High-Speed Data Capture

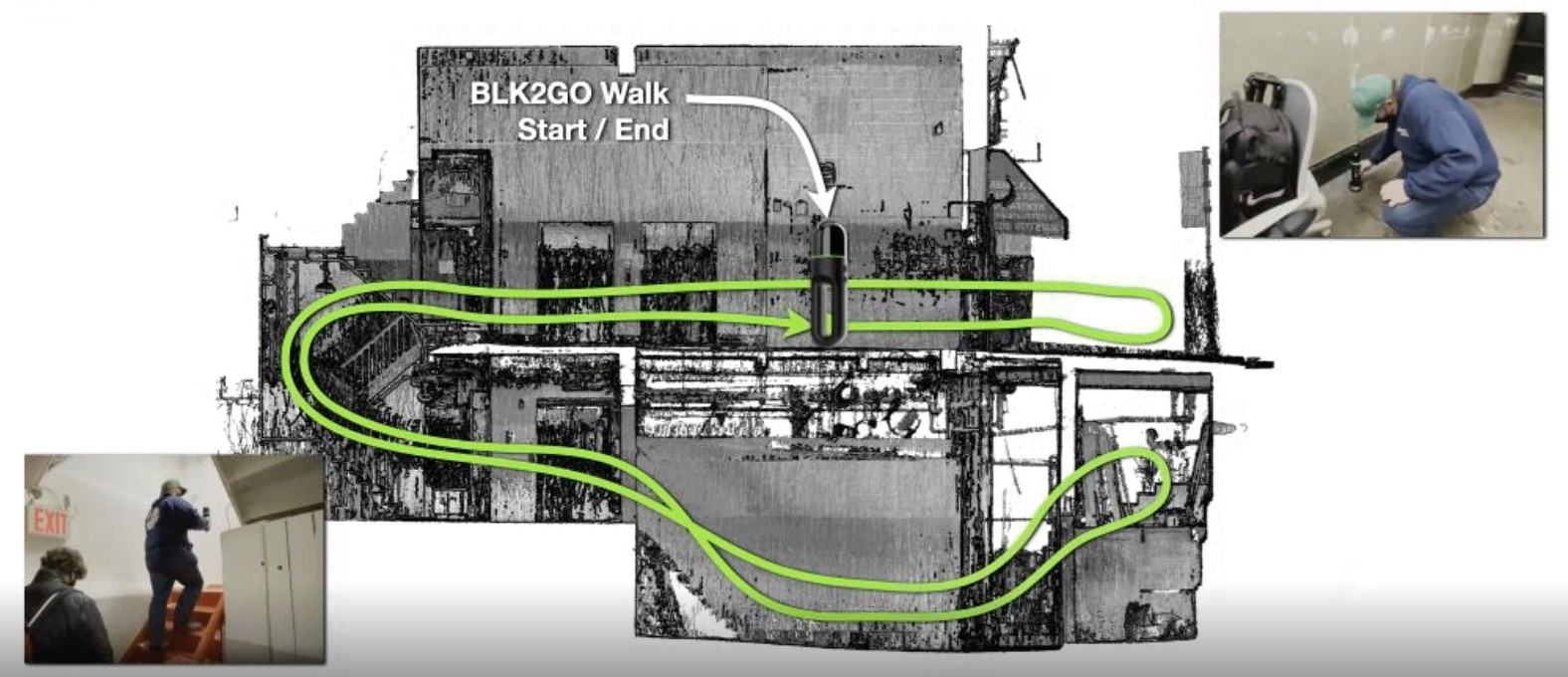

For each vault, the operator walked into and out of the target vault space with the BLK2GO, a process that usually took only 5 to 10 minutes. The scanner automatically calculated its 3D position and movement through 3D space and created a point cloud of the vault comprising millions of measurement points. A second 5- to 10-minute walk was performed to ensure the integrity of the reality capture, using a different route than the first if possible, to provide overlapping data. No additional surveying equipment was needed.

The speed of data capture helped the firm meet their project objectives and compensate for the unknowns in the project while opening the door to new opportunities in the future.

McLaren crews also scanned enough of the sidewalk area in front of the building to orient the vault measurements to previously completed topographic surveys of the intersections. To ensure correct orientation, the McLaren team also used their RTC360 laser scanner to scan each intersection in the project. While the original intersection surveys had been done conventionally and required two to three days per intersection, the team was able to capture as many as six intersections in a single day with the RTC360, which further increased project efficiency.

After importing all the scan data to Leica Cyclone REGISTER 360 point cloud registration software, the team extracted the limits of the vaults and cross sections in TopoDOT software, completed the drafting and then generated the final reports.

Innovative Approach Leads to Project Success

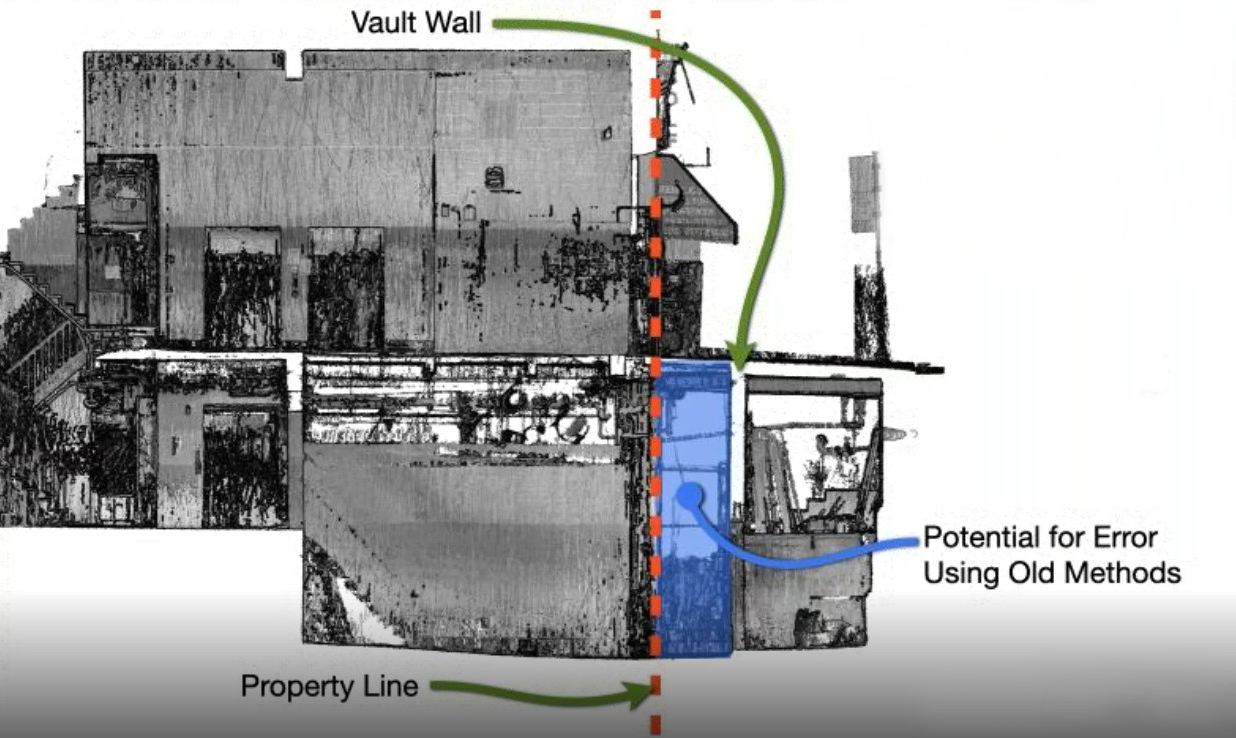

Using the handheld mobile laser scanner allowed the team to catch errors that might have otherwise gone unnoticed. Areas where the floors and ceilings were not level were clearly visible in the point cloud captured with the BLK2GO. In one case, a property supervisor stated that one wall of the vault was aligned with the property line, but the data from the BLK2GO showed the anecdotal information was incorrect; the vault extended several feet farther under the street than expected.

Importantly, the speed of data capture helped the firm meet their project objectives and compensate for the unknowns in the project while opening the door to new opportunities in the future.

Larson remembers that when the mobile scanner came out, he initially dismissed it as a surveying tool.

“I didn’t really pay much attention to it until this project came along,” he said. But “for this particular project, the BLK2GO was the right tool to use.”

For areas that are hard to reach with larger scanners or require extreme speed, the BLK2GO offers an easy, efficient way to capture accurate point cloud data. And as forward-thinking firms like McLaren work with the technology, additional applications in surveying and engineering are likely to emerge.

“We’re trying to push the bounds a little bit and see what it is really capable of doing,” Larson said.

Note: This insight is from the webinar, Surveying Reimagined: How Ingenuity and Innovation Create New Opportunities. Watch the full webinar here >

To talk to one of our experts and learn more about solutions for surveying and mapping, please contact us.