Utility surveying is a growth opportunity for many surveying firms. Like other surveying specialties, it requires the right expertise and technology. Radio frequency (RF) pipe and cable locators are the most common tools, followed by electromagnetic locators. But these methods only detect conductive (metallic) objects.

Increasingly, utility surveys also need to be able to locate, detect and trace underground pipes and cables that are nonmetallic. For this application, ground penetrating radar (GPR) is the go-to technology. However, the level of skill and training required to interpret the results has traditionally limited the widespread adoption of GPR.

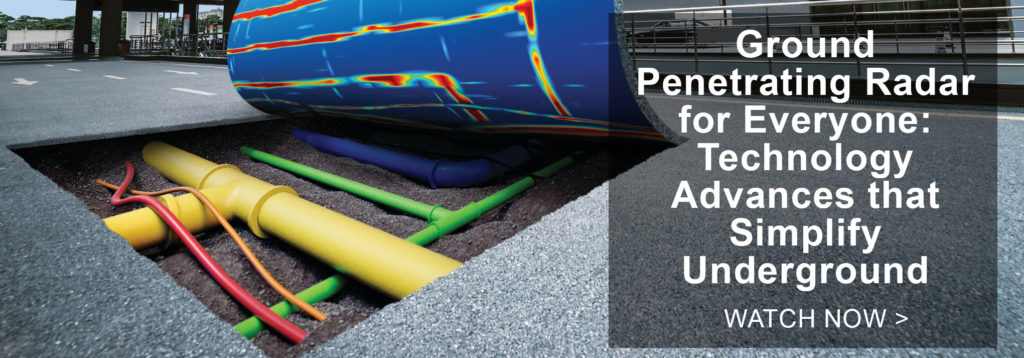

The animation above illustrates a radar in action. The screen on the top right provides squiggly information called a radar gram. As the GPR moves along the ground, it keeps track of its position, and the software organizes the data received from the signals. That data is presented on the radar gram as a hyperbola for the user to review. The various shades of gray represent signal strength. If we want, we can easily add more information to it – GPS or GNSS or total station data. This gives us the ability to export the GPR results to the 3D mobile world. We can take the data from the tool and go and do something else with it in the office through post-processing.

But if you haven’t used GPR before, the radar gram is a little confusing. You don’t know if you’re looking at a cable, a pipe or something else. It’s not clear what those bumps on the screen represent. Learning how to read a radar gram is not a quick and simple process. Data can be misinterpreted, and utilities can be missed. To expand the benefits of GPR, a new approach is needed that makes detection more accurate and more accessible.

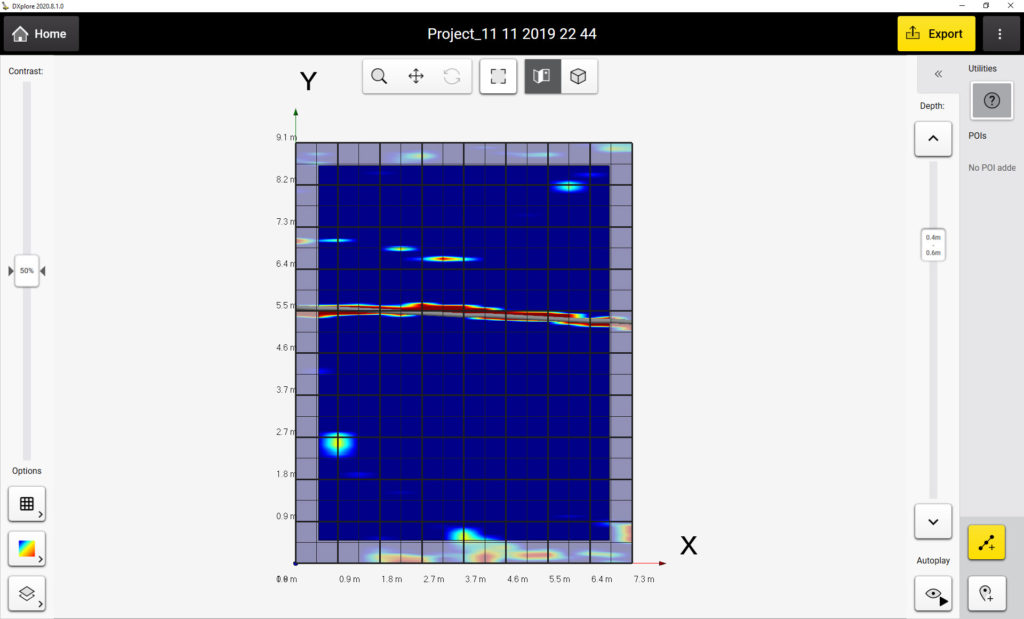

The solution is found through advances that change how we interact with the technology and visualize the results. The most recent GPR innovations feature large, daylight-readable screens that make it easy to setup the system, integrate GNSS, define the collection grid and access project information.

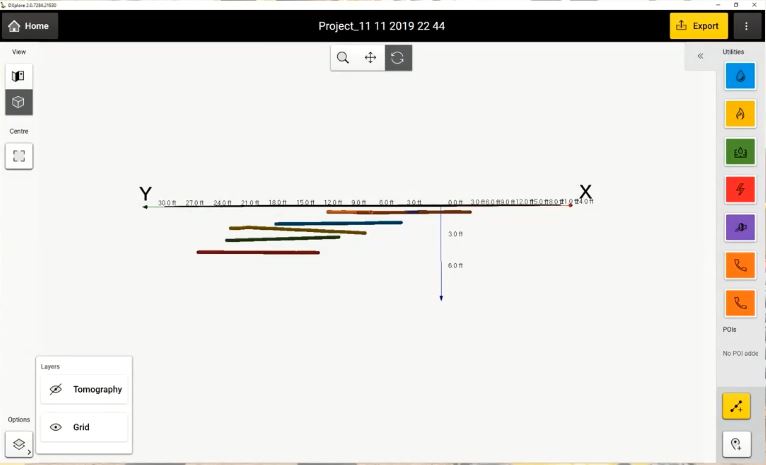

Results are displayed in real time using tomographic imaging, which is significantly easier to interpret than a hyperbola. We can look for a visual indicator that we have a utility. From there, we can rely on intelligent algorithms in the software to identify the utility and the exact location—the x,y position as well as the depth.

We can also see the utilities in 3D and how they interact with each other, so we can easily identify any conflicts and determine the best place to dig to avoid a utility strike.

And we no longer have to wait until the data is sent to the office and post-processed—that information is all available in the field immediately. The data can go in any coordinate system. We can also include other points of interest, such as fire hydrants, lamp posts and manholes, which adds even more context.

With the latest technologies, we can easily capture a complete and accurate picture of what’s happening underground. This capability expands our service potential and value.

About the Author:

Simon Pedley has been involved in the utility detection market for more than 17 years, providing technical support, field support and training during much of his career. As a detection solutions specialist for Leica Geosystems, Simon focuses on helping professionals in surveying, engineering and construction understand and implement technology to achieve damage prevention, safety monitoring and high-value utility mapping. He specializes in solutions from IDS GeoRadar and Leica Geosystems, which are both part of Hexagon and offer a seamless digital approach to utility detection.

Simon Pedley has been involved in the utility detection market for more than 17 years, providing technical support, field support and training during much of his career. As a detection solutions specialist for Leica Geosystems, Simon focuses on helping professionals in surveying, engineering and construction understand and implement technology to achieve damage prevention, safety monitoring and high-value utility mapping. He specializes in solutions from IDS GeoRadar and Leica Geosystems, which are both part of Hexagon and offer a seamless digital approach to utility detection.

To talk to one of our experts and learn more about how to use technology to your advantage, please contact us .