Combining the speed of a tilt rover with the automation of stylesheets has propelled Challenger Geomatics to the forefront of high-efficiency surveying for large-scale renewable energy projects.

In the transportation, residential, commercial and industrial sectors, electricity use is on the rise. A U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) study indicates that widespread electrification, driven in part by the shift to electric vehicles, could increase electricity consumption nationally as much as 38% by 2050. Canada’s electricity demand is even higher.* Large solar farms promise reduced carbon emissions and a renewable energy source to meet the increasing demand. But finding the most cost-effective way to build these farms requires the problem-solving expertise of forward-thinking surveying firms.

“Large solar farms start with the layout of hundreds of thousands of steel piles to set the foundation for the racking and photovoltaic panels,” explains Mike Fretwell, ALS, CLS, P.Surv., vice president of Calgary Operations for Challenger Geomatics Ltd. “These projects aren’t complex in and of themselves, but the requirements the contractors have in terms of showing progress and meeting deadlines can be challenging. We’re always looking for ways to help ease the pressure on our clients so they can achieve a more profitable installation.”

“The ability to eliminate the wait time for survey work is a big deal. By speeding up that process and approvals, we’re helping clients get to their billing cycles much faster.”

“The ability to eliminate the wait time for survey work is a big deal. By speeding up that process and approvals, we’re helping clients get to their billing cycles much faster.”

– Mike Fretwell, ALS, CLS, P.Surv.

Based in Alberta, Canada, with offices in Edmonton, Calgary, Whitehorse, Yellowknife, and Fort McMurray, Challenger Geomatics has a reputation for quality surveying, mapping and remote sensing services as well as creative problem solving. “If you look at the DNA of Challenger, it’s really sort of a maker organization,” Fretwell says. “Even a few decades ago we were solving some really cool problems by implementing new technologies, new techniques, writing code. That hasn’t changed.”

When the company was tasked with the layout of 228,000 steel piles for Canada’s largest solar farm, Challenger Geomatics was already recognized as one of the most efficient surveying firms in the renewable energy sector in Canada. But as work began on the project in the spring of 2021, Manager Legal/Construction Surveys Drew Stodalka thought they could do better.

Challenger’s survey technology dealer, Spatial Technologies, had reached out to them months earlier about one of the newest GNSS receiver technologies with tilt compensation, the Leica GS18 T. The ability to measure points without stopping to level the pole promised a substantial increase in speed. As part of Challenger’s technology lease program with Leica Geosystems, upgrading from their existing GNSS rovers was a relatively easy proposition; when their existing lease ended, they could simply trade up to the next-generation equipment for a comparable monthly payment. It just made good business sense.

The field staff embraced the change and doubled down on their efforts to increase productivity on the solar farm project. “Conditions can be very harsh on the Canadian prairie, with near continuous wind and winter temperatures, but there is a feeling of accomplishment in overcoming adversity to deliver,” explains Fretwell.

The tilt capabilities of the GS18 T, combined with the diligence of the field crews, shaved seconds off each measurement, which added up to significant time savings. Crews were able to lay out piles up to 25 percent faster, completing hundreds of additional piles per day.

“Personally, I had some reservations about the GS18 T until I saw how well it performed in this context,” admits Fretwell. “Drew won’t even consider using a different type of receiver for layout now because of the effectiveness of the GS18 T on this project.”

Field Productivity Boost Creates Data Management Opportunity

The faster data collection helped ensure the solar project would stay on track with no surveying-related delays. But it also created a new challenge: Significantly more data from the field crews needed to be processed to meet the client’s daily 10 am data review deadline. The improved field productivity was creating a bottleneck in the office.

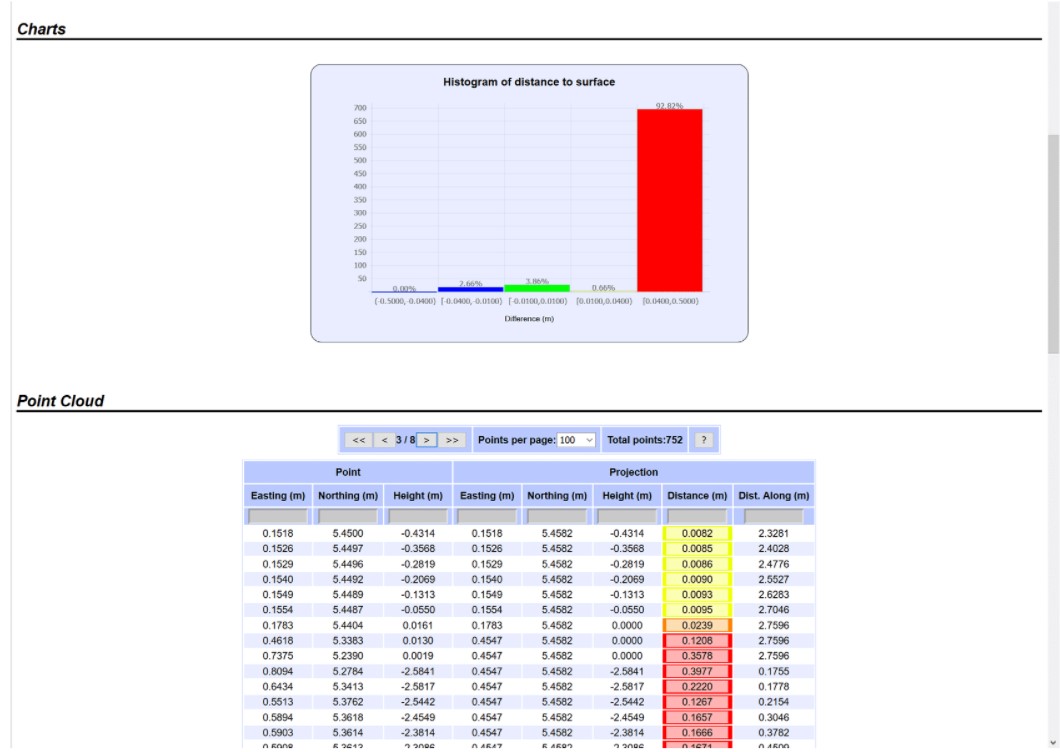

“We had nine crews in the field, and we were taking everything from the Captivate field software into Infinity office software for processing,” explains Megan Hartery, survey technologist for Challenger Geomatics. “That’s a lot of points being processed into CSVs or other formats. A lot of steps were required to copy data over, crop data out and try to filter through everything.”

Hartery spent hours every morning on repetitive data processing and management tasks, starting earlier each day, but she couldn’t work fast enough. She was also keenly aware that every manual touch of the data increased the potential for errors.

Fretwell saw the situation as another opportunity. “One of the things I wanted to bring to Challenger was change management,” he says, “and there’s never a better time to implement change than in the middle of a project when things aren’t going as well as you’d like.”

Stylesheets Automate Workflows for Optimum Efficiency and Quality

Fretwell had experience working with format files, which have been used for data export since the late 1990s. Using the Format Manager PC tool, the user can select a set of export variables and load them into a controller or instrument to define how data is exported from a job. The process is easy and works well with basic GNSS receivers and total stations used on simple projects. But the increasing sophistication and functionality of survey instruments over the last two decades have revealed the limitations of format files. They simply aren’t adaptable enough.

Enter stylesheets. A highly flexible technology that is used in numerous software industries to define export parameters, a stylesheet can be created to produce an Excel spreadsheet directly from the survey instrument without requiring intermediate steps or data conversions. Stylesheets can also be created to produce a desired HTML file, including CSS styling and even Javascript, to allow clients to interact with the data. This type of file can be displayed in any browser in an easy-to-read visual report.

For a project with repetitive processes, like the solar farm, stylesheets provide an easy way to automate data processing.

Fretwell knew Leica Geosystems already offered a library of stylesheets with Captivate field software, but he also felt confident that with a little training he could learn to develop his own. After taking the online learning courses available through the Leica Geosystems MyWorld customer support portal, Fretwell dove right in, relying on support from Leica Geosystems’ Alastair Green, Burke Asay and their teams to help answer questions and resolve issues.

Creating and implementing the stylesheets was a collaborative process, with Stodalka and Hartery, as well as Geomatics Technologist Mandy Rammer and Office Resource Manager Stefan Helmer, contributing process definition, optimization and troubleshooting. “Consistent, constructive collaboration leads to positive outcomes,” Fretwell says.

Using the stylesheets, the Challenger crews now generate at the field level the daily reports required by the client. This allows Hartery to focus on more high-value tasks, such as creating formal reports and maps, organizing the data, and responding to other project needs as they arise. The time savings is substantial, but even more important is the increased repeatability in the office.

For a project with repetitive processes, stylesheets provide an easy way to automate data processing.

“If I have to hand the work off to someone else, it’s easy for them to pick it up,” Hartery says. “And anyone who’s worked with massive amounts of data knows that it’s almost an order of magnitude more likely that a mistake is going to happen with each iteration of processing. Using stylesheets allows us to minimize that risk.”

Innovation Drives Client and Employee Happiness

Not surprisingly, Challenger isn’t done innovating their processes. Fretwell and Stodalka are now refining project accounting to track every variable. Implementing automated error checks, flags and notifications will enable the system developed on the solar farm to be rolled out across the entire company to benefit every project.

Contractors for renewable energy projects and other large-scale projects that require innovative thinking and creative problem-solving are taking notice. And the company culture attracts talented people to Challenger and makes them want to stay, which brings the value of innovation full circle.

“The ability to eliminate the wait time for survey work is a big deal,” explains Fretwell. “By speeding up that process and approvals, we’re helping clients get to their billing cycles much faster. If they can bill an extra 1500 piles because we’re a day in advance of where they thought they were going to be, they’re much better off. That’s a tangible benefit. Our clients also appreciate the risk mitigation, project management and collaborative approach we bring to their projects.”

“Being innovative is Challenger,” says Hartery. “Everything I’ve seen people do here is innovative, and if they don’t have a way, they’re going to find or make a way. It makes me proud to be part of the company, and I enjoy it immensely.”

To talk to one of our experts and learn more about solutions for surveying and mapping, please contact us.